How ESAF Compares

ESAF TradeCo delivers superior performance across key metrics, combining the best attributes of specialized aerogel products with breakthrough multi-functional capabilities.

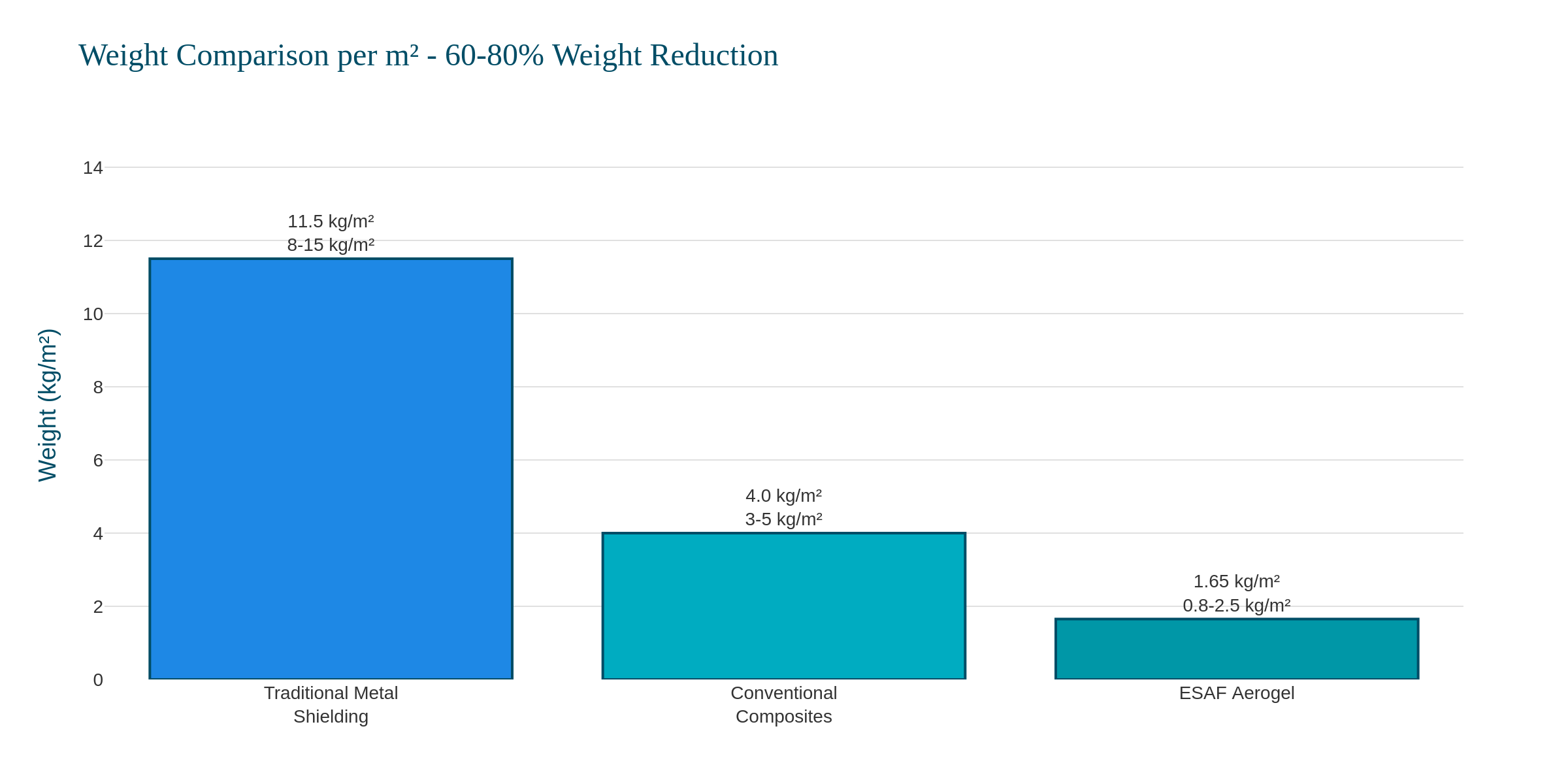

Weight Comparison

Detailed Comparison

Side-by-side comparison with industry leaders like Aspen Aerogel and conventional materials.

| Feature | ESAF TradeCo | Aspen Aerogel | Conventional |

|---|---|---|---|

| Weight (per m²) | 0.8-2.5 kg | 3-5 kg | 8-15 kg |

| EMI Shielding (dB) | >40 dB | 30-40 dB | 80-120 dB |

| Thermal Conductivity | 0.012 W/m·K | 0.013-0.015 W/m·K | 0.025-0.045 W/m·K |

| Temperature Range | -260°C to +650°C | -200°C to +400°C | -40°C to +150°C |

| Multi-Functional | Yes (EMI, thermal, corrosion) | Primarily thermal | Single function |

| Cost vs Performance | Optimal | Higher | Low (but heavy) |

ESAF Advantages

What sets ESAF TradeCo apart in the advanced materials market.

60-80% Weight Reduction

Significantly lighter than Aspen Aerogel and conventional materials, critical for aerospace and automotive applications.

Multi-Threat Protection

Unique combination of EMI shielding, thermal insulation, and corrosion protection in a single material system.

Extreme Temperature Performance

Operational range from cryogenic (-260°C) to high-temperature (+650°C) exceeds competitor capabilities.

Military-Grade Specifications

Meets or exceeds MIL-STD-461G and MIL-STD-188-125 requirements for defense applications.

Custom Engineering

Tailored solutions for specific applications, from UAV electronics to pipeline coatings.

Cost-Effective Manufacturing

Ambient pressure drying and scalable processes reduce production costs by 50-70%.

Experience the ESAF Advantage

Discover how our advanced aerogel technology can give you a competitive edge in your market.